Description -

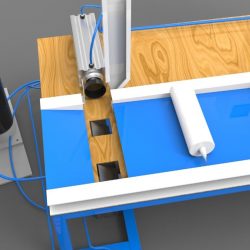

Drumpress/ pail extruder/ pail pump is a simple, robust single component dispensing system can easy pump out a wide range of materials. It offers chemical resistant, hardened parts making it both durable and low maintenance.

This single component system is heavy duty and it easily dispenses fluids or adhesives.

It offers a 25 kg and 250 kg tank and can dispense materials up to 1.5 lac cps viscosity.

This system is built on a portable cart and with simplicity in mind, making it affordable, reliable, and easy-to-use.

It can simultaneously run two hand guns allowing for double the output.

Use this system with a wide range of viscosity materials including silicone, polyurethane and polysulfide.

Features -

- High flow-rate pumps and guns

- Priming piston (shovel) type suction for high viscosity fluids.

- Superior quality spares to reduce maintenance cost.

- Auto shut off for pumps

- Facility for twin pall switchover system

- Drum capacity 20 lit and 200 lit.

- Custom built system for more drum capacity with special features

- Separately heating system with PLC base control

- Temperatures of individual heated parts can be visible on HMI Display with special security features

- Hydraulic Stroke count possible to check per day material consumption (optional)

- Air consumption monitoring (optional)

Specifications -

|

SR.NO |

SP. TYPE |

20 KG |

200 KG |

|

1 |

TYPE |

55:275 |

75:210 |

|

2 |

RATIO |

55:1 |

75:1 |

|

3 |

OUTPUT/CYCLE(CC) |

275 |

210 |

|

4 |

AIR MOTOR PISTON DIA.(mm) |

300 |

300 |

|

5 |

STROKE LENGHTH (mm) |

120 |

120 |

|

6 |

APPROX. WEIGHT (kg) |

67 |

100 |

|

7 |

RECOMMENDED DISPENSE VOLUME PER MINUTE (LIT.) |

7.5 |

6 |

|

8 |

AIR INLET PRESSURE MAX. (bar) |

6 |

6 |

|

9 |

OUTPUT PRESSURE MAX (bar) |

330 |

450 |

|

10 |

AIR CONSUMPTION Lit/min. MAX |

5000 |

5000 |

Applications of drmpress

- Solar applications

- Cartridge filling

- Any kind of drum emptying/ transfer application for viscous and semi viscous fluids

- 2K mixing

- Seam sealing

- Glass glazing

- Spot weld

- structural sealing

- Two component epoxy resin dispensing

The dispensing method can be selected as per your application. We offer the following dispensing methods:

- Manual dispensing

- Automatic stationary.

- CNC dispensing.

- Scara robot dispensing

- Robotic arm dispensing

- Conveyor dispensing.